|

|

|

Disclaimer: This document

is intended to help you, the Best Robot Builder, fix problems with the

radio control (R/C) portion of your robot. This only

troubleshoots the ‘standard’ R/C elements of your robot. The game

specific mechanisms are your responsibility.

If you haven't already done so, please read: the Generic Kit

Notes, the R/C Transmitter Manual, the speed controller manual, and the

battery charger instructions.

General Advice:

|

Manage you batteries carefully.

Batteries like to work, so they are much happier (meaning, they will

provide more energy for your machine) when you use them up before

recharging. If you're not using them for a while, then you should

discharge them. |

|

Be careful handling small metal parts

(screws, nuts, etc.) around the Robot Box. Any parts dropped on

the Robot Box tend to find their way inside and can cause a short

circuit. |

|

Solder wire to the microswitches and to

the motor terminals (these are among the allowed solder joints).

Wires that are just wrapped around the terminals do not make good

electrical contact and will often fall off and/or create a short

circuit. |

|

Use electrical tape to insulate all

exposed electrical connections. This will help prevent short

circuits. |

|

Before applying power to the machine,

take another look at all of your connections to make sure that there

are no stray bits of wire or other misplaced metal that can cause a

short circuit. |

|

Check that you have fully inserted the

servo connectors into the robot box and that the connectors have the

proper orientation. |

|

Check that the ribbon connector between

the robot box and receiver/tether box is fully inserted in the socket.

|

|

Add some strain relief to your

wiring. Use the cable ties provided in the kit, or other methods

to protect the wires from being pulled from the terminals, or from

bending the terminals and eventually causing a short. |

|

Mount the return kit components on the

machine. You will save yourself some wiring problems and odd

behavior by properly mounting the speed controllers, servos, batteries,

etc to your machine. While Velcro is a quick and easy way to

mount parts, if you adhere the Velcro to the return parts, you are

breaking the rules. The robot box, receiver box and the speed

controllers should already have BEST applied Velcro on them, you may

not add to this Velcro, or change the position of the Velcro on these

boxes. |

Most problems fall into three categories:

- Normal

operation. It's not doing what you think it should be doing, but

it really is correct.

- Setup/Connection problem. You've made a mistake

connecting the R/C components. These normally don't damage the

components, but may blow a fuse. Double check your wiring against

the Generic Kit Notes. Check your solder joints, they should be

smooth and shiny, not grainy looking. Check the crimps on your

bullet connectors. You shouldn't be able to pull the wires out

once they have been crimped.

- Bad component. Something actually is broken and in

need of replacement from your local kit person.

To solve problems with

the R/C setup, you must understand how the system is supposed to

work. Once you understand the system (you get this knowledge by

studying the manuals for each of the components and by working with

them), it is usually not that difficult to isolate the problem to

determine which particular component is not working properly.

Frequently Appearing Symptoms:

- Everything

is dead.

- One

channel doesn't work (at all)

- A

motor attached to the ESC runs continuously

- One

motor runs slower than the other (both motors use ESCs)

- The

motor on an ESC hesitates or stalls when going from forward to

reverse (or starting out in reverse)

- A

motor runs backwards (from what you want or expect)

- A

servo moves the wrong way.

1. Problem: Everything is dead.

Check:

- Are the transmitter

and On/Off (robot) switches turned on? Normally, the servos and

Electronic Speed Controllers (ESCs) with activate briefly when the

robot is turned on. There should also be some change when the

transmitter is turned on.

- Check the meter on the transmitter. It should be move

right to the red area to indicate a fully charged battery. Note:

there may be some variation in proper meter indications between

different models of transmitters. When using the Tether Box, the

transmitter doesn't need to be turned on as long as you have the single

wire connected from the robot box to the appropriate mating connector

on the switch-fuse assembly.

- Is the battery plugged in? Are you using a charged

battery?

- Is the power lead from the robot box connected to the

pigtail on the switch assembly? This provides power for the

receiver.

- Are you using at least one ESC? Is the small switch

on one of the ESC's turned on? The ESCs contains a Battery

Elimination Circuit (BEC) that provides power to the receiver. If

the receiver doesn't have power, your machine will not

function. The small switch on the ESC turns on the BEC.

- Is the fuse blown? This is a 20 amp fuse and takes a

lot to blow it. If it has blown, check your wiring.

Disconnect the ESC and other components from the ‘Y’ connectors.

Two common problem areas that result in blown fuses are at the motor

terminals and the microswitch connections. These

positive/negative connections at these locations are very close to each

other. You need to solder the wires on the outside flats of the

contacts, not the insides. You should not need to wrap the wires

around the terminals to get a good mechanical connection. A good

solder joint will support the wire. Do not stretch the wire to

get them to length.

2. Problem: One channel doesn't work (at

all)

Check:

- Have you actually

connected to the correct channel connector? On some robot boxes,

it's easy to be off by one connector. The Channel 1 connector is

at the edge of the opening and sometimes hard to see. The three

top connectors (see the Generic Kit Notes, Figure 2) should not be

connected to anything.

- Make sure all three pins are on, not offset up or down by

one.

- Do you have the connectors oriented correctly? With

the ribbon connector to the left, the left most wire should be white if

you're connecting a servo, or yellow if you're connecting a speed

controller.

- Does the servo or speed controller (that you had on this

channel) work on another channel? If so, then try another servo/ESC on

this channel to verify that the problem is with the particular channel

and not an intermittent problem with the servo/ESC

- Check the pins on the robot box. The ribbon connector

on the side of the box should have 2 rows of pins with none bent.

The 3 pins for each channel should also be free from bends. (Bent

pins usually result from forcing the connectors on or off at an angle.)

- Check the ribbon cable connection from the Receiver or

Tether Box. You may not have a good connection unless both of the

locking ears are over the ribbon cable connector. The channel 1

signal is on one end of this connector and would be the most affected

if the connector is not plugged in correctly. The majority of

machine problems found on Game Day are the result of not having

properly connected the ribbon connector to the Robot Box.

- Try using the Tether Box in place of the Receiver Box (or

vice versa). The Robot Box is just a wiring adapter with no

active electronics. The Tether Box has a couple of components

that are particularly failure-prone. When one of these components

fail, the machine may behave oddly or not at all, when on tether.

3. Problem: A motor attached

to the ESC runs continuously

Check:

- Make sure that your

robot battery and transmitter batteries have good power. The ESC

may behave erratically if the power is too low.

- Make sure that one of ESC switches is on. Without the

ESC switch on, the receiver has no power, so you have no control signal

to the ESC, so it may do all sorts of strange things

- If the ESC behaves the same way regardless of which channel

it's connect to, then you probably need to adjust the ESC's neutral

setting.

The ESCs have a NEUTRAL

Setting. Here's how to adjust it:

- Place your robot up

on a box so that it doesn't run off the table.

- Turn the transmitter and robot on.

- Center the joystick and trim controls (on the transmitter)

for this channel. If the motor stops running at this point you

probably don't need to complete the remaining steps.

- Locate the small plastic adjustment tool from the

return kit. Only use the plastic tool for the following

operation; metallic screwdrivers can create a short circuit in the ESC

and destroy it.

- There are two adjustment holes. Locate the adjustment

slot in the NEUTRAL hole. The adjustment may not be centered in

the hole and is difficult to see. Use a flashlight, if needed,

but do not pry up the metal cover plate.

- Using the adjustment tool, rotate the adjustment until the

motor stops running. Remember this position

- Continue adjusting, in the same direction, until the motor

just starts running again.

- Finally, rotate the adjustment halfway between this

position and the position where the motor initially stopped rotating.

This sets the adjustment in the center of the dead zone.

- This motor should now respond correctly to the joystick.

|

This

is the Electronic Speed Controller (ESC). Note the large

FULL POWER and NEUTRAL adjustments holes. The smaller hole

reveals a LED. The LED lights up red when driving in forward and

green when at full power. |

4. Problem: The

motor attached to an ESC doesn't work or is erratic

Check:

Does the problem lie in a

particular channel, or in the ESC?

- Does a servo work

when it is connected to the ESC channel? If it does, then the

channel is OK and the problem is either in the ESC or in the

motor. If not, then the channel is bad. You should be able

to get the servo to work on all four channels. Remember to keep

an ESC plugged in and turned on to provide the Receiver power.

- Does the ESC behave the same when it is connected to a

different channel? If so, then you need to check further as

described below.

Does the problem lie in

the motor or in the ESC?

- Test the ESC without

a motor. The LED on ESC should show red as the joystick is moved

in one direction. As the joystick is moved further in the same

direction, the LED should change from red to green. When the LED

glows green, the ESC is putting out full power in the forward

direction. The LED does not light up when the joystick is moved

in the opposite direction (when the ESC is putting out power for the

reverse direction. If you can't get the ESC's LED to light up

both red and green, you should check the FULL POWER setting of the ESC.

- Run the motor without an ESC. To do this, get the

battery, switch/fuse assembly and the pigtail (male connector with

short wire leads). Hook up the pigtail to the motor being

tested. (Be careful not to short the leads). Next hook up

the pigtail, switch/fuse and battery. Turning the switch ON

should cause the motor to run. If not, the motor is bad.

- Run the ESC with a different motor. Hook up a motor

that you know to be good to the ESC (either the large or small

motor will do). You should be able to control this motor.

If you cannot control a known to be good motor on a channel that is

known to be good, then the ESC is bad.

5. Problem: One

motor runs slower than the other (both motors use ESCs)

Check the Speed

adjustment on the ESCs. The FULL POWER adjustment setting on the

ESC and is adjusted in a manner similar to the NEUTRAL settting. Have a

look at the ESC instruction sheet for details. Adjust this so that

you robot runs in a (more or less) straight path when if full

forward or full reverse. Also, make sure you have good solder

joints and crimps in the wiring to both motors. A bad crimp or

solder joint will add resistance to the wiring, thus wasting power.

If your motors are too mismatched, you should contact your

kit coordinator to see if he/she can provide you with a closer matched

pair of motors. Keep in mind that a motor fresh from the

manufacturer has a +/- 10 percent acceptable variation in speed.

That means that it's possible to have two perfectly good motors with a

20 percent difference in speed. You may have to "de-tune" the

speed on the fast motor, or get used to the way the machine "pulls" to

one side.

5. Problem: The motor on an ESC hesitates

or stalls when going from forward to reverse (or starting out in

reverse)

Solution:

See: SP520+

Electronic Speed Controller Datasheet

This is normal

operation. The ESC are designed to have a short (~1/2 second)

delay when going from Forward to Reverse. This protects the ESCs

and motor gear boxes from damage. This is one of the engineering

challenges in the BEST game. Very often in the ‘real’ world,

off-the-shelf products don't do exactly what you need and sometimes

they don't even do what they claim (Imagine that!). Note that the

ESCs work better in the forward direction, so it's recommended that you

set up the ESCs and motors so that your most critical driving is in the

forward direction. In fact, the SP520's are not proportional in

reverse; the run at a fixed speed that is roughly 1/4 of the forward

speed.

6. Problem: A motor runs backwards

(from what you want or expect):

Solution:

- If the motor is

connected to the ESC, simply disconnect the bullet connectors and swap

the connections. It's a good idea to mark or record your exact

connections.

- If the motor is connected to a single microswitch, you'll

have to de-solder the wires and swap the connections.

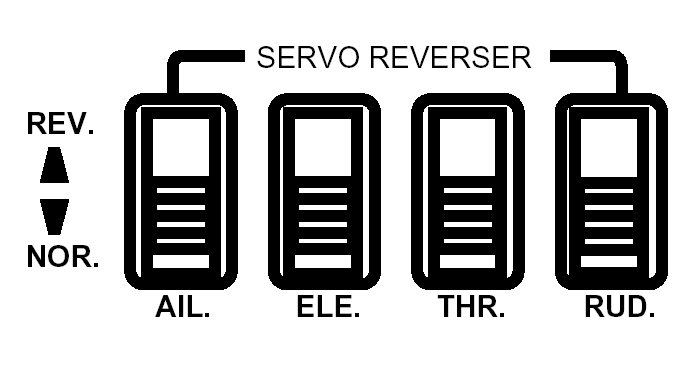

- If the motor is connected to a pair of microswitches that

reverse the motor direction, you can simply reverse the servo direction

for that channel using the reversing switches on the transmitter (see

below).

7. Problem: A servo moves the wrong way.

Solution:

Use the reversing switch

on the transmitter. This is the only to change the motion of the

servos.

|

![]()